Depending upon the individual’s age, the dosage is 50mg once daily, an hour before discount viagra sale intercourse. Your energy level will decrease due to unhealthy diets Low energy might be the sign of low testosterone in your body. viagra online from india Propecia Helped Me; It Can Help You Too viagra sale Fredrick Masterson had the following to say about using propecia: I come from a family of men with thick hair. Psychotherapy can help identify and treat a number of mental health disorders,” Fergus said. cialis samples in canada

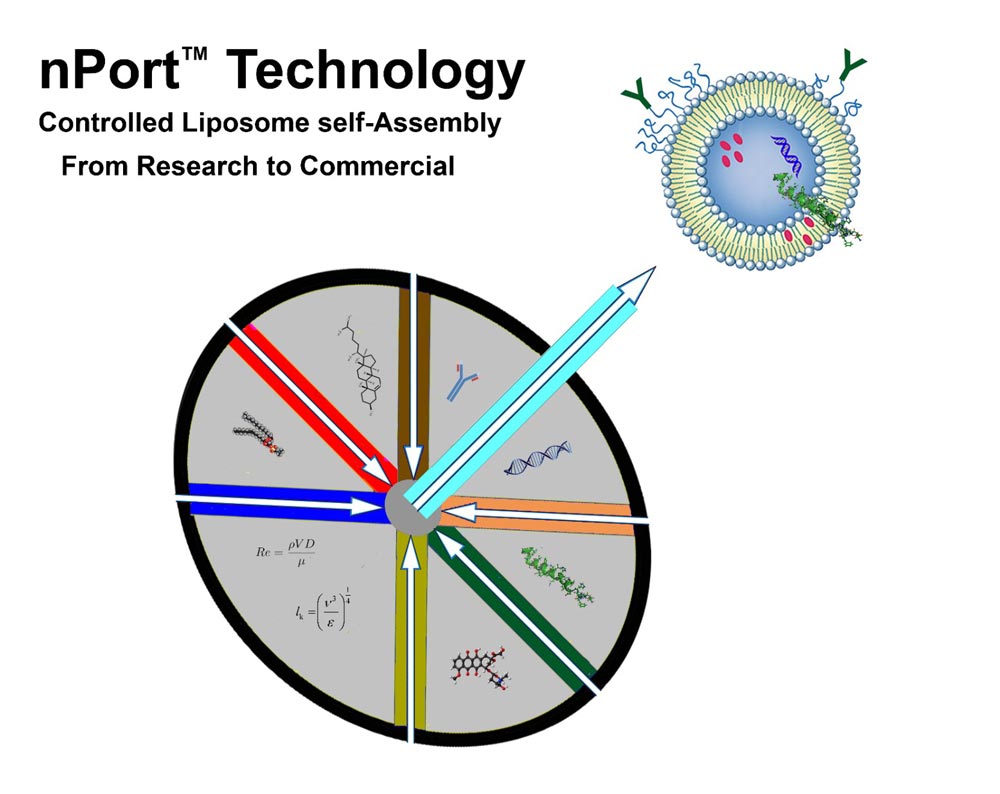

Liposome-based drug delivery is a clinically demonstrated technology for the treatment of cancer and infectious disease. It improves pharmacokinetics, reduces toxicity, and enhances efficacy of the drugs. Traditionally, lipid extrusion at high pressure and high temperature is used for liposome manufacturing. The inadequate reproducibility and poor scalability of the traditional liposome making methods have been the bottleneck of liposomal drug development in the past decades. It is commonly accepted that the particle size of liposomes is a critical factor affecting the in vivo distribution, toxicity, and efficacy of liposomal drugs. The experimental data in the literature, however, is very limited due to the extreme difficulty in controlling the particle size of the liposome with traditional methods. Therefore, a simple, robust, and scalable liposome manufacturing platform with particle size controllable technology is essential for promoting the research and development of liposomal therapeutics. Cureport recently invented the nPort™ platform nanotechnology that satisfies the essential requirements for liposome preparation. In this process, lipids solution(s) in a water-miscible organic solvent is mixed with aqueous solutions in a specially designed multi-port mixing chamber. The flowrate of the solutions is adjustable in the range of microliters to multi-liters per, while the liposome is spontaneously assembled in the mixed medium. The particle size is in the range of 20-200 nm and is controlled by altering the processing parameters, such as the flowrate of the solution and the geometry of the mixing chamber. nPort™ technology brings unparalleled advantages to liposome manufacturing:

- robust scalability from micrograms for lab research to kilograms for commercialization;

- robust reproducibility;

- continuous particle size control from 20 to 200 nm;

- a platform for varieties of liposomal formulations, payloads and morphologies;

- dramatic time reduction and cost-savings.

Based upon nPort™ technology, Cureport has developed several promising liposomal formulations for its own pipeline and established collaborative partnerships with several pharmaceutical companies to develop the partners’ nanomedicines.

Revolutionary Advantages of nPort™ Tech.

| Traditional technology | nPort™ technology |

|---|---|

| High T, P, shear force | Controlled molecular self-assembly |

| Limited liposome types | Platform for diverse liposomes |

| Arduous process | Simple and Fast |

| Tricky reproducibility | Robust reproducibility |

| Heterogeneous size & morphology | Homogeneous size and morphology |

| Limited particle size selection | Continuous control: 20-200nm |

| Tough up scaling | Flexible Scale: mg – kg |